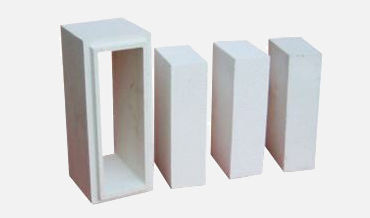

Fireclay Brick

Hard Fireclay bricks are alumina silicate bricks with the refractoriness of SK 32-34 and contain 35- 45% alumina. The bricks are made from various raw materials of fire clay, calcined chamotte, mullite etc . They are highly resistant to abrasion, spalling and corrosion.

High Alumina Brick

High alumina bricks of over SK35 contain over 45% Alumina and are made from raw materials of unusually high degree of purity of Bauxite and refractory clay. For serve under severe conditions,JUCOS Alumina bricks have excellent mechanical strength, good resistance to thermal spalling, and are highly resistant to chemical attack by vilatile alkaies and some slag.

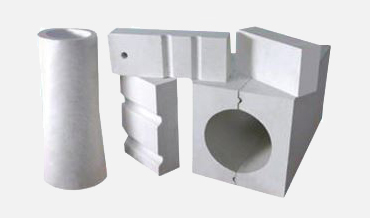

Special Alumina Brick

Special Alumina Bricks are made by high grade of sillimanite,andalusite,mullite, corundum as raw material, It can resist corrosion of molten and corrosion of industrial slag. with high refractoriness, low creep and mechanical behavior under high temperature, high refractoriness under the load,good thermal shock resistance and slag resistance.

Corundum Brick

Corundum Brick have stable quality and excellent durability. These products are made mainly of calcined alumina, mullite, corundum of high purity. These brick have low porosity, excellent hot strength and creep resistance, and good volume stability at high temperature, Jucos Corundum Brick have been developed to meet the most demanding specifications for various industrial applications.

Silica Brick

Silica brick is made of silicon as raw material with high temp firing ,which silicon oxide is above93%, used in hot blast furnace,coke oven,glass kiln,these brick have good volume stability at high temperature, high refractoriness under the load,small rate of shrinkage in working condition.

Silicon Mullite Brick

The raw materials for this product are good quality bauxite and SiC, being pressed and sintered. The products have high CCS, good mechanical strength, well thermal shock resistance, and the protection layer could be formed during service, which leads to very good spalling result and thus always be used for transition zone, cooler and hoops in cement industry.